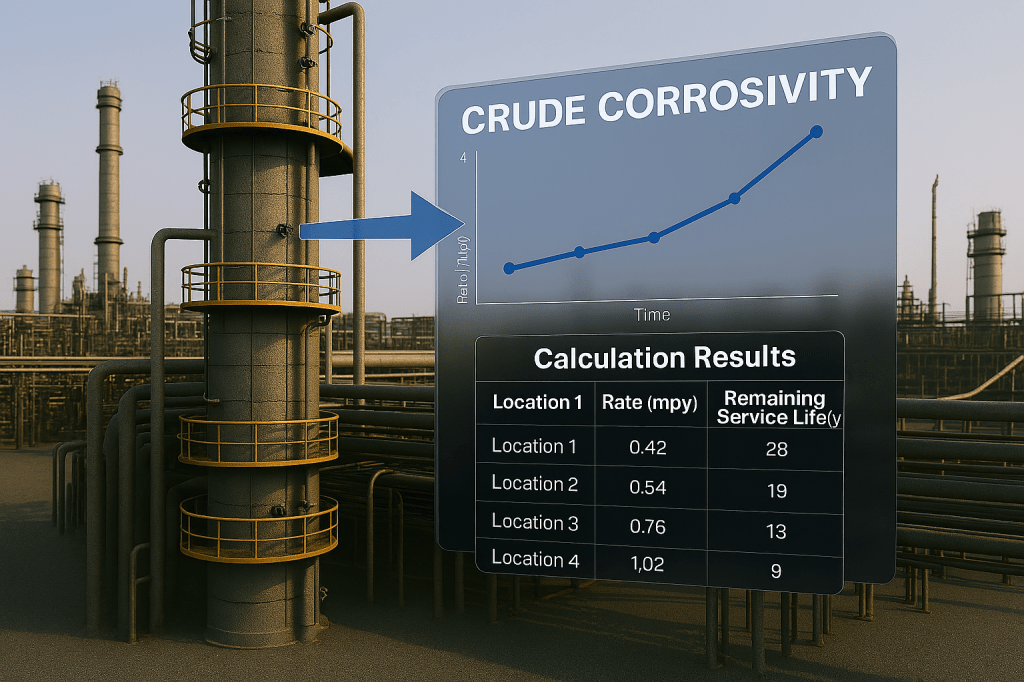

Naphthenic acid corrosion and high temperature sulfidation are the main corrosion drivers in the hot sections of crude distillation unit. Sometimes described by the term “crude corrosivity”, these damage mechanisms are responsible for most of major incidents in crude distillation units. Increasing unit throughput, blending sour and acidic crudes, or changing the distillation profile may create conditions that lead to accelerated naphthenic acid corrosion and/or sulfidation.

Crude-Corrology® can help operators and engineers to assess corrosion risks related to these damage mechanisms.

This model combines key process parameters, including temperature, total acid number (TAN) and sulphur concentration with flow modelling to provide actionable insights that support process evaluation, Integrity Operating Window (IOW) development, and inspection planning.

🎯 Register for Free Trial

Each registered user receives three complimentary runs in total, applicable across all models on the platform.

Your free registration gives you the opportunity to:

- Explore model capabilities and evaluate crude corrosivity.

- Evaluate the effects of process conditions such as temperature, flow dynamics, and TAN/S.

- Generate insights to support IOW development and inspection planning.

- Compare corrosion risk scenarios under varying operating conditions.

- Experience the platform interface and assess its value for your operations.

💡 Start Today

Visit the Knowledge Library, register for free, and see how the Crude-Corrology® model can enhance your decision-making and corrosion management strategies.

#Corrology #Corrosion Modelling #Crude Corrosivity #Flow #Asset Integrity #Sulfidation # Naphthenic Acid Corrosion

Leave a comment