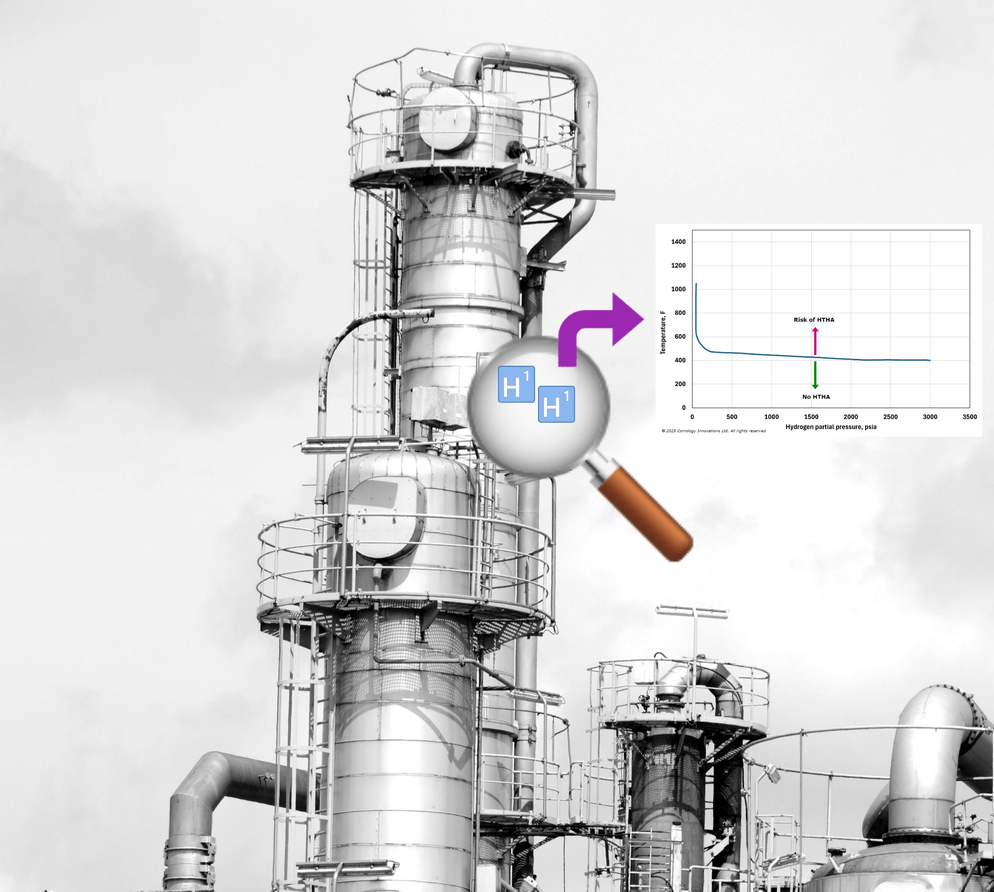

High-Temperature Hydrogen Attack (HTHA) is a critical damage mechanism that affects the integrity of carbon and low-alloy steels exposed to high temperatures and elevated hydrogen partial pressures. Commonly found in Hydroprocessing units – such as hydrotreaters, hydrocrackers, and hydrogen production facilities – HTHA can silently compromise equipment integrity through internal decarburization, posing significant safety and reliability risks.

🧪 What Is HTHA and How Does It Begin?

At its core, HTHA is driven by a chemical reaction in which hydrogen reacts with cementite (Fe₃C) to form methane gas within the metal lattice.

This trapped methane accumulates, building internal pressure that leads to microcracks, voids, and blistering, which degrades the steel’s mechanical integrity over time. While this reaction offers a simplified view of HTHA, the full mechanism includes multiple steps: hydrogen adsorption, diffusion, and a series of radical reactions that contribute to the damage. 📌

📊 What Influences HTHA Susceptibility?

Several key factors affect how quickly and severely HTHA can develop:

🔹 Carbon content in the steel

🔹 Hydrogen partial pressure

🔹 Operating temperature

🔹 Applied stress (both primary and secondary)

🔹 Type and amount of alloying elements

An understanding of these variables is critical for making key decisions on:

✅ Material selection

✅ Inspection planning

✅ Equipment design and operating envelopes

🛠️ HTHA Assessment Tool

Traditionally, HTHA risk has been evaluated using empirically derived Nelson Curves, which outline risk thresholds based on temperature and hydrogen partial pressure.

To support this evaluation, we’re offering an HTHA assessment tool that applies Nelson Curve principles to help estimate susceptibility and guide decision-making.